ORION ELECTRONICS

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to ORION ELECTRONICS

Package Solution

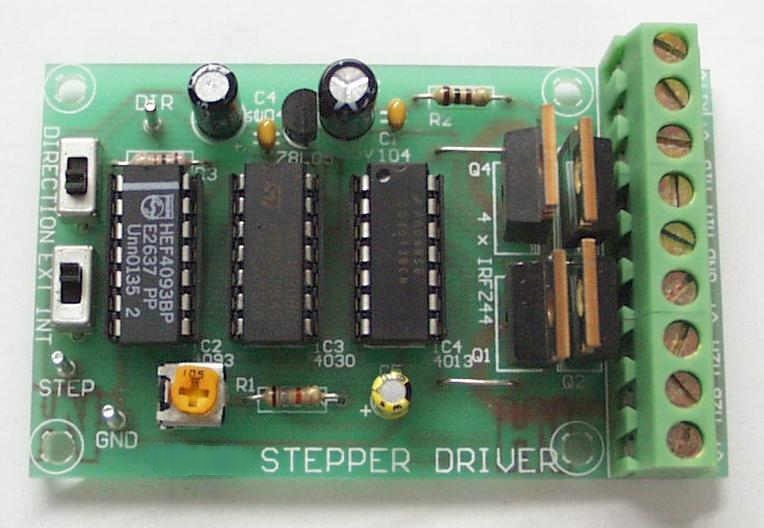

Since a long time, we have been solution providers to stepper driven industrial processes. Many customers prefer to have drive, controller and power supply all packaged together. Going by that, we offer complete machine automation solution with overall logic as embedded system all packaged into a single Panel or a Cabinet comprising of following or more components, all wired systematically. Over the years we have developed many different enclosures, table-top and otherwise.

Our Panel, would consist of VFDs, Transformers, Temperature Controls, Unwinder controls, synchronized motion with AC motor, sensor inputs along with our drives and controller. The Cabinet (a small sized panel), comprises only of our Drives and Controllers along-with the transformers. This ensures reliability and is a space-saver. Our panels come in varied sizes and are electrically insulated and proper care is taken to ensure adequate earthing.

Having said the above, a lot of customization is possible and we can design a panel specifically as per your requirement. For eg., we can provide the above setup along-with an encoder counter, which helps in speed matching between two motors and also for position tracking. Synchronization with pulse, time and operations become absolutely feasible.

We can offer you the above model as a blind controller or a separate stand-alone controller.

Cabinet System Panel System

2, 3 axis Servo Panel

Orientation System

We offer our Orientation System for Filling & Sealing Machine. ORION “Tube Orientation Drive” is compact and reliable equipment, which has many optional features to suit the need of machine designer.

Instant start / stop is the unique property which makes it an ideal application for stepper motors. The motor starts when the start sensor activates. However, for any reason if the stop sensor does not activate; the motor may go on rotating. To avoid this, a timer can be incorporated which will stop the motor after set time, even if stop sensor signal is received. Some machine builders employing a more supervisory system, need a signal from the drive, when motion of the motor ceases.

Orion Orientation Systems can be controlled through following ways :

1. Stop on mark sensor with added time-out stop in absence of mark sensor

2. Stops when start sensor de-activates in absence of mark sensor

3. Stops specific number of steps after mark sensor activates

4. Slows down when mark sensor activates and stops when it de-activates.

5. Stay put or timed relay output on every stop also possible

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.